New technology developed at WSU will help doctors grow cancer-fighting white blood cells

Washington State University chemical engineers have created new technology with the potential to treat cancer faster and cheaper than before.

A minifridge is able to produce cancer-killing white blood cells, or T-cells, 30% faster than current technologies. Authors of a new paper in the journal Biotechnology Progress have conducted successful animal trials growing the T-cells of cows. If successful in upcoming human trials, lead researcher and WSU postdoctoral student Kitana Kaiphanliam said she hopes the new technology will have “global” implications.

“The manufacturing demand for this growing number of therapies is not being met, so there is a gap that needs to be filled in terms of biomanufacturing solutions,” Kaiphanliam said. “At the end of the day, they need to be upscaled, so they can be used by more people.”

The T-cells produced in the body are the body’s natural defense against ailments. But cancer can “outsmart” the body, Kaiphanliam said, and “downregulate” its ability to produce these white blood cells that fight the cancer.

Those treating certain forms of cancer can isolate the T-cells in a patient, grow those T-cells outside of the body and then reintroduce a larger number of cells into the patient.

In 2022, more than 1,400 different types of therapies using T-cells were in development, with seven approved by the FDA for a variety of cancer treatments. But use of the therapy is limited because of the cost and time needed to grow T-cells. Each infusion treatment for a cancer patient requires as many as 250 million cells.

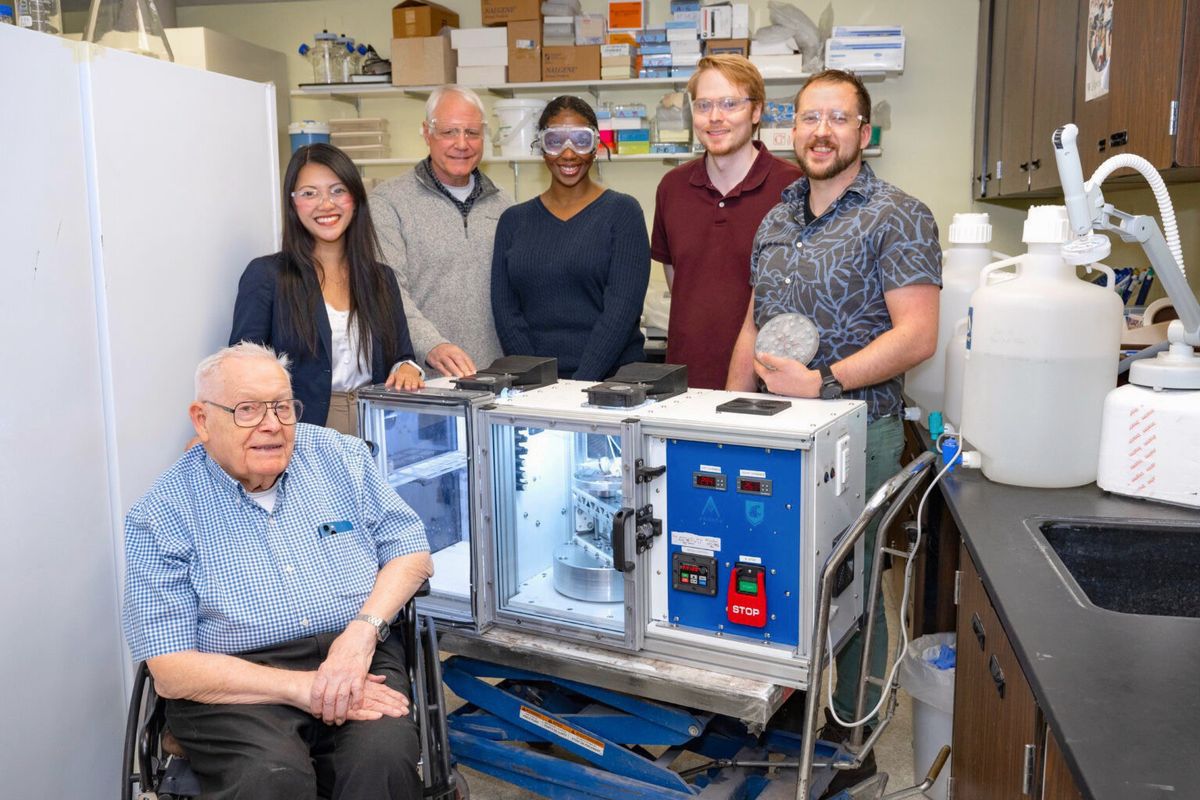

The centrifugal bioreactor developed at WSU rapidly densifies and expands cells – all contained in a small box. Researchers expect the finished product will produce enough cells in three days for three doses of a therapy, which is quicker than current technology.

Another benefit to the bioreactor is that it can be self-contained within a sterile cabinet of moderate size, which means the centrifuge does not need a “clean room” that avoids contamination.

“This is important because the spiral reactor can be used in other countries who don’t have the same access to clean room facilities as we do here in the states. And so ultimately that democratizes cell therapies and access to cell therapies,” Kaiphanliam said. “We envision these bioreactors being used in hospitals and cancer centers and cancer research institutes, where they have multiple of these devices to grow cells for multiple patients in parallel.”

Kaiphanliam and fellow paper author Brenden Fraser-Hevlin have founded for-profit company Ananta Technologies to further develop their bioreactor and get it into as many medical facilities as possible.

“As I continued to work on the bioreactor and do research with it, I just had this feeling that I really didn’t want to see something that has so much potential to help save lives be stuck in an academic laboratory. That’s why I’ve started my own company,” she said. “It always takes somebody who’s going to commercialize that tech so it can be used in the real world. And I didn’t want to wait around for somebody else to do it.”

WSU chemical engineering professor and paper co-author Bernie Van Wie said the technology is proof of WSU’s place as an elite research institution.

“WSU is a Research One institution. So for us to come up with ideas that are groundbreaking – that is something we should do,” Van Wie said. “If you get the right kind of people on board, then you can see things that WSU are creating will make a big difference.”

Because of human trials and regulatory validation studies, Kaiphanliam anticipates three to five years before the centrifuge is seen in hospitals. Once on the market, cost for the bioreactor will likely be around $100,000, Kaiphanliam said, noting other technologies that generate these T-cells can cost hospitals anywhere from $50,000 to $300,000 apiece.

But the initial success of the technology is validating to the research team, which has been working on the project since 2016 that is based on decades of WSU research.

“It was in 2016 when we had the idea to apply this previous research to cancer treatment. But this is really an idea since the creation of man, or at least the inception of disease. How do we combat that? That drive is in our nature,” Van Wie said.

The research was supported by the National Science Foundation, the Washington State University Gap Fund, a Palouse Club Cougar Cage grant, the Washington Research Foundation and Scientific Bioprocessing.